|

spindle upgrade

the 1000 lb. front spindle upgrade

disclaimer: part numbers change frequently and i have no control over this.

as a result these links may become outdated before i can update them. northern tool 4 bolt trailer hub

http://www.northerntool.com

northern tool 1" spindle for above hub

http://www.northerntool.com

OR, combination 4 bolt hub and spindle package from northern tool

http://www.northerntool.com 4 bolt wheel for the above hub

http://www.cedarrapidstire.com

|

|

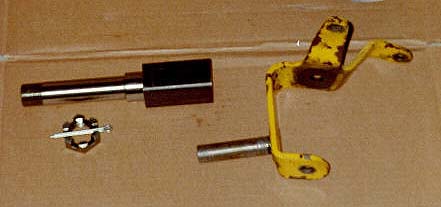

parts collection

|

original 3/4" spindle

|

|

|

1. start by cutting off the old spindle then grind the surface of the spindle bracket smooth.

|

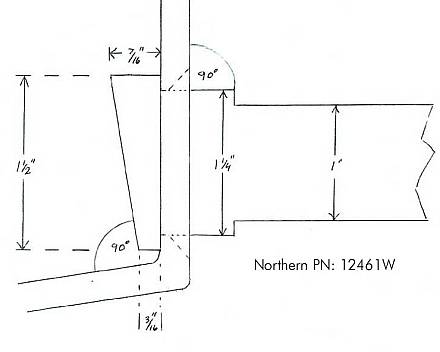

2. with a 1-1/4" bi-metal hole saw, provide a hole to accept the new stub axle shoulder. remember to put a large chamfer on the outside of the spindle bracket for welding. weld inside and out.

|

|

|

3. box in the spindle bracket with 1/4" plate steel and weld inside and out.

|

4. make sure your outer weld is contained within the chamfer because you only have 1/8" between the spindle bracket and the new hub assembly.

|

|

|

5. install the hub, pack with grease and check clearances.

|

|

|

|

the Cub 1000lb. front alxe... now you won't have to wonder if the front end can take it.

|

6. install your tires on the new rims and you're all set.

|

|

|

What if you should have the "L" shaped spindles like on this 1968 Gilson 12HP??

|

here is an idea from Doug H. he kept his existing 3/4" L-shaped spindles on the tractor and just bored out the Northern Tool spindle to fit over it.

|

|

|

Here is a real nice fix sent in by one of our customers in Medford, OR. he reused the stock steering arms and incorporated them into a completely new "C" shaped spindle carrier, then used the 1" spindles, etc from Northern Equipment.

|

the bored out spindle slips over your existing spindle....

|

|

|

this is the finished product complete with 4 bolt hubs and tapered roller bearings, you can't get much stronger than this.

thank you Stan C.

|

and is held in place by the cotter pin at the end running through both spindles. this allows you to upgrade to the tapered roller bearings and a 4 bolt hub without changing your current "L-shaped" spindle configuration

|

|

|

here is another idea of how to upgrade spindles on an older sears craftsman garden tractor. Jon L. from East Greenwich, Rhode Island sent these in. nice work Jon!

|

and if for some reason you want to go back to your original setup, just pull the cotter pin at the end of the spindle and slide on your original wheels and hubs

|

|

|

Jon bored the new spindle through at a 12 degree angle to keep the alignment straight with the axle, then welded in a new pivot pin.

|

this is the finished product using the original steering arms on the linkage.

|

|